Understanding Cellulose Ether and Its Applications

What is Cellulose Ether?

Cellulose ethers are a versatile class of chemical compounds derived from cellulose, a natural polymer found in the cell walls of plants. Through a series of chemical processes, well-defined structural modifications are applied to cellulose to produce ethers such as methyl cellulose, hydroxypropyl cellulose, and ethyl cellulose. These modifications enhance their functional properties, making them suitable for a variety of industrial applications. The resultant cellulose ethers are typically water-soluble and can form gels, reducing agents, and thickeners, making them highly advantageous across diverse sectors.

Common Uses of Cellulose Ethers

Cellulose ethers are utilized widely across different domains, including pharmaceuticals, food production, personal care products, and construction. In the pharmaceutical industry, they serve as excipients in drug formulations, providing improved solubility and stability. In food manufacturing, cellulose ethers act as thickeners, stabilizers, and emulsifiers, enhancing texture and shelf-life. Personal care formulations, from lotions to shampoos, benefit from their ability to enhance viscosity and film-forming properties. Additionally, in construction, cellulose ethers improve the workability of cementitious products, increasing adhesion and reducing water loss during application. These applications underscore the importance of understanding the production processes within a Cellulose ether factory to ensure consistent quality and performance.

Benefits of Using Cellulose Ether in Industry

The advantages of using cellulose ethers in various industries are manifold. One significant benefit is their non-toxic nature, which makes them suitable for use in food and pharmaceutical products. Their ability to control viscosity and provide thickening agents enhances the stability and performance of formulations. Moreover, cellulose ethers can form thermoreversible gels, allowing for innovative applications in drug delivery systems. Furthermore, their biodegradable characteristics are increasingly valuable in the context of environmental sustainability, aligning with global initiatives aimed at reducing synthetic polymer usage. Using cellulose ethers facilitates the development of safe, effective, and environmentally friendly products.

Key Processes in a Cellulose Ether Factory

Raw Material Sourcing and Preparation

The production of cellulose ethers begins with the sourcing and preparation of raw materials. The primary ingredient is cellulose, typically sourced from wood pulp or cotton linters. Once sourced, the cellulose undergoes purification to remove impurities that can affect the quality of the final product. This purification process is critical, as it ensures that the cellulose retains its functional properties during the subsequent chemical modifications. The prepared cellulose is then subjected to milling to achieve the desired particle size, a pivotal factor that affects the solubility and performance of the cellulose ethers produced.

Manufacturing Processes of Cellulose Ethers

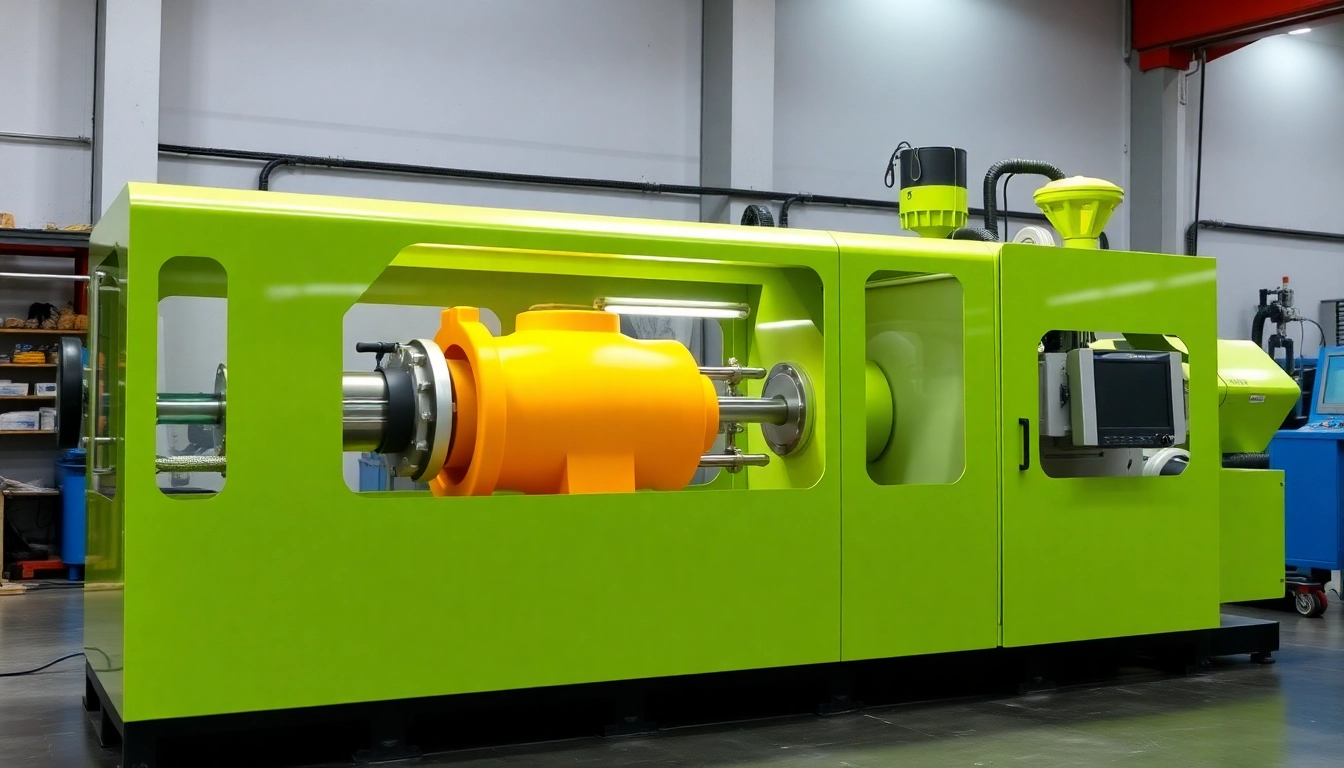

The core manufacturing processes of cellulose ethers involve chemical reactions that convert cellulose into its etherified forms. This is primarily done through etherification processes, where cellulose is reacted with various etherifying agents, including methyl chloride, ethylene oxide, or propylene oxide, under alkaline conditions. The choice of agent and reaction conditions is critical as they influence the properties of the final product, such as solubility, viscosity, and thermal stability. After etherification, the resultant cellulose ethers are neutralized, washed, and dried before being milled to achieve the desired particle size and packaging for distribution. Advanced facilities utilize state-of-the-art equipment to ensure consistency and quality throughout the production cycle.

Quality Control Measures in Production

Quality control is imperative in the manufacturing of cellulose ethers to ensure conformity to specifications and regulatory requirements. Factories typically implement a series of testing protocols that include raw material inspections, in-process checks, and final product testing. Analytical techniques such as High-Performance Liquid Chromatography (HPLC), spectrophotometry, and viscosity measurements are employed to ascertain product consistency and quality. These measures help to minimize variability and ensure that the cellulose ethers meet the specific needs of various applications. Maintaining rigorous quality standards not only enhances customer satisfaction but also protects the brand reputation of manufacturers.

Technological Innovations in Cellulose Ether Production

Automation and Smart Manufacturing

The advent of automation in cellulose ether production has led to significant improvements in operational efficiency and product quality. Automated systems facilitate real-time monitoring of production processes, allowing for immediate adjustments to maintain optimal conditions. This minimizes human error and enhances the reproducibility of results. Furthermore, the integration of Internet of Things (IoT) technologies enables factories to collect and analyze data, providing insights that can inform process improvements and predictive maintenance strategies. The result is a streamlined production environment characterized by increased output and reduced operational costs.

Energy Efficiency in Cellulose Ether Factories

Energy efficiency is a key concern in cellulose ether factories, not only for cost savings but also for reducing the environmental footprint of production processes. Innovation in energy management systems allows manufacturers to monitor energy consumption effectively and implement energy-saving measures. Techniques such as waste heat recovery, energy-efficient machinery, and process optimization can lead to substantial energy savings. Moreover, employing renewable energy sources can enhance sustainability efforts further. By prioritizing energy efficiency, cellulose ether factories can contribute to a greener planet while maintaining competitive production costs.

Future Trends in Chemical Production

Looking ahead, the cellulose ether industry is poised for transformation driven by several emerging trends. One notable trend is the increasing shift towards sustainable raw material sourcing. Manufacturers are exploring bio-based alternatives to traditional cellulose sourcing, aligning with global sustainability targets. Additionally, advancements in biotechnology are paving the way for more efficient production methods through enzyme-assisted processes. Another significant trend is the growing importance of circular economy principles, particularly in waste management and resource recovery. Factories that adopt these principles will likely benefit both environmentally and economically, as they become more resilient to supply chain disruptions.

Challenges Faced by Cellulose Ether Factories

Compliance with Regulatory Standards

With the increasing scrutiny on chemical products, compliance with regulatory standards has become a major challenge for cellulose ether factories. Manufacturers must navigate a complex framework of regulations that vary by region and application. This includes ensuring that products meet safety, health, and environmental standards. Keeping up with changes and new requirements can be resource-intensive, requiring dedicated teams to manage compliance efforts. Failure to comply can result in significant financial penalties and reputational damage, making proactive compliance strategies essential for successful operations.

Managing Supply Chain Disruptions

Supply chain disruptions are another pressing challenge in the cellulose ether manufacturing sector. Factors such as geopolitical instability, natural disasters, and pandemics can severely impact the availability of raw materials and interrupt production schedules. To mitigate these risks, manufacturers are increasingly adopting diversified sourcing strategies and building robust relationships with suppliers to ensure flexibility and responsiveness. Furthermore, investing in supply chain analytics can provide insights into potential risks and enable more proactive management. Effective supply chain resilience not only minimizes disruptions but also enhances overall operational efficiency.

Environmental Sustainability Practices

As environmental concerns gain traction globally, cellulose ether factories face pressure to adopt environmentally sustainable practices. This includes managing waste, reducing water consumption, and minimizing emissions during production. Implementing green chemistry principles, using renewable energy sources, and streamlining processes to eliminate hazardous materials are steps that can enhance sustainability. Many manufacturers are now setting measurable sustainability goals and reporting on their progress to stakeholders. Being a leader in environmental stewardship can provide a competitive edge as consumers and businesses increasingly favor environmentally responsible products.

Performance Metrics for Cellulose Ether Factories

Key Performance Indicators (KPIs)

To gauge the efficiency and effectiveness of operations within a cellulose ether factory, establishing Key Performance Indicators (KPIs) is essential. Common KPIs include production yield, cycle time, and defect rates. Production yield measures the quantity of finished product versus the raw materials used, reflecting the efficiency of the production processes. Cycle time assesses the time taken from raw material intake to product packaging, indicating overall operational speed. Monitoring defect rates helps manufacturers maintain product quality and compliance with industry standards. Regular analysis of these metrics can inform strategic decisions and drive continuous improvement initiatives.

Assessing Production Efficiency

Assessing production efficiency involves a systematic review of resources utilized, outputs generated, and time spent across all production stages. Lean manufacturing principles are often applied to identify waste and inefficiencies, allowing for optimized resource allocation and workflow improvements. Techniques such as value stream mapping can help visualize processes and highlight areas for reduction. Efforts to improve production efficiency not only enhance profitability but also enhance the manufacturer’s ability to respond to market demands promptly.

Customer Satisfaction and Product Quality

Ultimately, the success of a cellulose ether factory hinges on customer satisfaction, which is directly correlated with product quality. Implementing a robust customer feedback system allows manufacturers to gather insights and adapt their products to meet evolving customer needs. Regular product reviews, coupled with adherence to quality standards, ensure that the cellulose ethers produced fulfill market demands. Satisfaction metrics, which can include customer complaints and product return rates, provide actionable insights. High customer satisfaction levels contribute significantly to brand loyalty and repeat business, reinforcing the importance of prioritizing quality.