Understanding Machine Vision

What is Machine Vision?

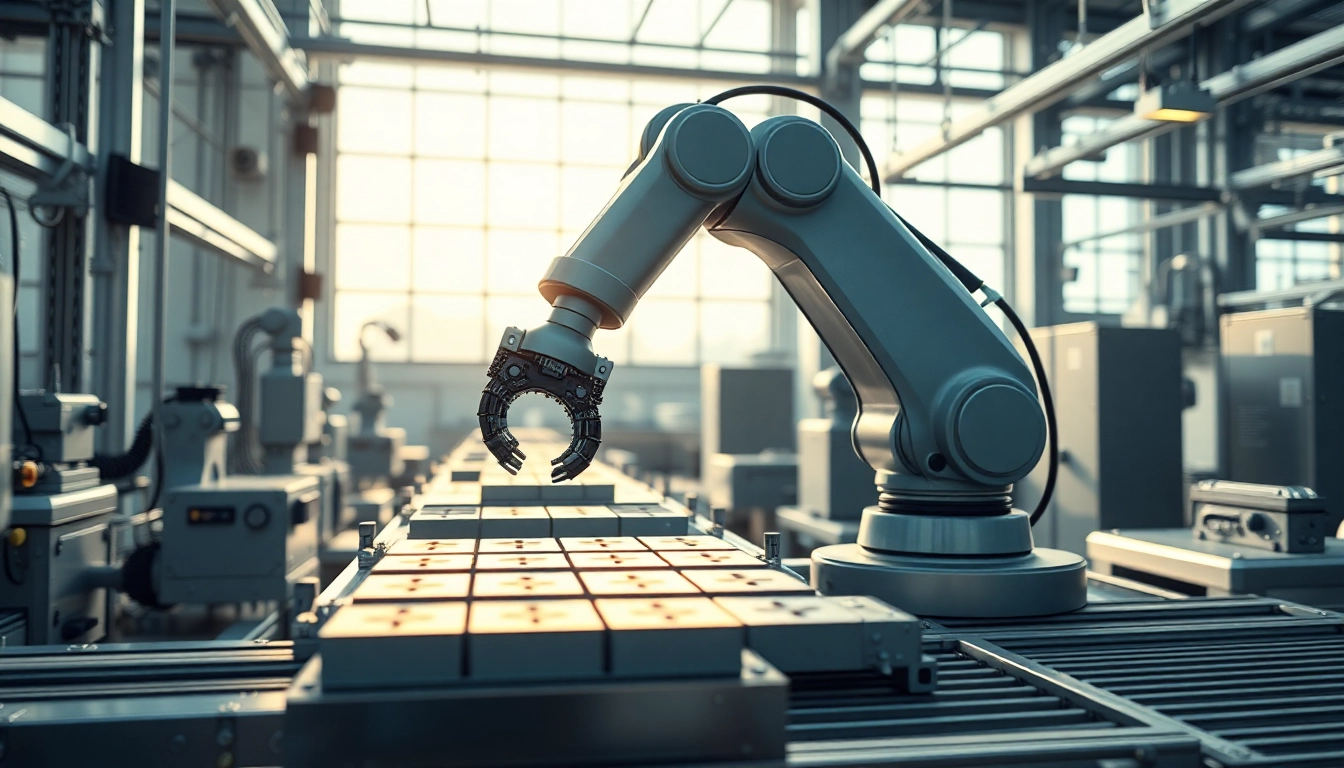

Machine vision refers to the capability of a computer or machine to receive and interpret visual data from the surrounding environment. Through this technology, machines can perform complex tasks involving image processing, analysis, and decision-making. By integrating specialized hardware like machine vision cameras and software algorithms, these systems can replicate human visual processes for applications in various fields, notably manufacturing and robotics.

Principles Behind Machine Vision Technology

The fundamental principle behind machine vision technology is to emulate human visual perception to automate tasks traditionally performed by humans. The process begins with image acquisition, where cameras capture visual information. This captured data undergoes processing, often involving a sequence of steps that include image enhancement, feature extraction, and analysis. The insights derived from this analysis allow machines to make informed decisions based on predefined criteria.

Types of Machine Vision Systems

Machine vision systems can be classified into several categories based on their functionality and application:

- 2D Machine Vision: This system captures flat images and is primarily used for applications like barcode scanning and defect detection.

- 3D Machine Vision: Utilizing multiple images from various angles, 3D vision provides depth information, allowing for complex applications like surface inspection and robotic guidance.

- Color Vision: Systems equipped with advanced sensors can analyze color variations, essential for quality control in manufacturing.

- Infrared and Thermal Imaging: These systems detect temperature variations and are critical in industries where heat signatures play a significant role, such as electrical inspections or monitoring manufacturing processes.

Applications of Machine Vision

Industrial Automation and Quality Control

Machine vision is instrumental in enhancing industrial automation scenarios, particularly in quality control. It plays a pivotal role in ensuring the consistency and quality of finished products. For instance, machine vision systems can conduct exhaustive inspections to detect defects in real-time, reducing the chances of substandard products reaching the market.

Machine Vision in Robotics

In robotic applications, machine vision enables robots to perceive their environment. Everyday uses include:

- Picking and placing: Robots equipped with vision systems can identify and handle items on a conveyor belt, optimizing operations in warehouses.

- Navigation: Autonomous robots use machine vision to detect obstacles and navigate dynamic environments safely.

- Collaborative Interaction: In collaborative robotics, vision systems allow robots to work alongside humans, enhancing safety and productivity.

Case Studies of Successful Implementation

Numerous industries have reported successful implementations of machine vision systems. For example, a leading automotive manufacturer leveraged machine vision for quality inspections on assembly lines. The improved error detection rate allowed them to significantly reduce recall rates and enhance customer satisfaction. Another case involved a food processing company that utilized machine vision systems for barcode verification and packaging inspection, leading to increased throughput and reduced human error.

Benefits of Machine Vision Solutions

Improving Efficiency and Accuracy

One of the primary advantages of machine vision is its ability to process vast amounts of visual data quickly and accurately. This technology eliminates the subjectivity associated with human inspection, leading to faster decision-making and reduced cycle times in production.

Cost-Effectiveness in Manufacturing

Investing in machine vision technology often results in long-term savings. By decreasing labor costs associated with manual inspections and minimizing waste through precise quality control, companies can bolster their bottom line. Additionally, with fewer defects, the cost tied to rework and returns diminishes.

Enhancing Product Quality

Machine vision systems ensure that products meet quality standards consistently. They can detect minute defects that might escape the human eye, thus ensuring only products that meet stringent quality criteria reach consumers. This level of scrutiny enhances brand reputation and customer loyalty considerably.

Challenges in Machine Vision Deployment

Technical Limitations and Solutions

While machine vision offers substantial benefits, there are inherent challenges, particularly regarding technical limitations. Issues such as lighting variations, complex backgrounds, and image noise can hinder performance. Solutions include:

- Adaptive Lighting: Implementing adaptive lighting techniques can help normalize illumination across different environments.

- Image Processing Algorithms: Advanced algorithms can mitigate noise and improve the clarity of visual information.

Integration with Existing Systems

Integrating machine vision systems into pre-existing workflows can pose challenges, especially if older equipment is involved. To address this, businesses should opt for modular systems that can interface with legacy systems or invest in software solutions that facilitate seamless data exchange.

Dealing with Environmental Factors

Environmental conditions, such as dust or temperature variations, can affect the functionality of machine vision systems. Employing robust protective measures, such as enclosures for sensitive components and temperature control mechanisms, can help mitigate these challenges, ensuring consistent performance in varied settings.

The Future of Machine Vision

Trends Shaping Machine Vision Technology

The future of machine vision is dynamic and evolving, driven by trends such as increased miniaturization of sensors, enhanced processing speeds, and the rise of Internet of Things (IoT) technologies facilitating smarter manufacturing processes. Furthermore, vision systems are becoming more accessible and affordable for small to medium enterprises, broadening their application across various industries.

AI and Machine Learning in Vision Systems

Artificial Intelligence (AI) and Machine Learning (ML) are playing transformative roles in machine vision. By incorporating AI algorithms, vision systems can analyze patterns and learn from data over time, improving their accuracy and decision-making capabilities. This approach allows for predictive maintenance, where systems anticipate failures before they occur, reducing downtime.

Market Outlook and Predictions

The machine vision market is projected to experience substantial growth. Reports suggest that advancements in AI, increasing automation, and a heightened focus on quality and safety standards will drive this expansion. As industries across the board adopt machine vision solutions, the technology is poised to integrate more seamlessly into automated environments, fundamentally reshaping manufacturing and operational processes.